Quality Assurance

Metrology

Ensuring Precision

The Art of Metrology at LBC

Ensuring the accuracy and quality of your project’s components is crucial. At LBC Engineering, we take precision to the next level through meticulous metrology practices.

What is Metrology?

In simpler terms, metrology is the science of measurement. It encompasses the principles, methods, and instruments used to ensure precise and reliable measurements. This ensures every component aligns perfectly with your specifications and performs flawlessly.

Why is Metrology Important?

Accurate measurements are at the heart of everything we do at LBC. They impact:

- Precise dimensions ensure components fit together seamlessly and operate as intended.

- Meeting strict tolerances is critical for safety-critical applications.

- Minimizing errors prevents costly rework and delays.

Our Commitment to Metrology

We utilize advanced coordinate measuring machines (CMMs) and other state-of-the-art equipment to perform a wide range of measurements, including:

- Dimensional Inspection: Verifying length, width, height, and other critical dimensions.

- Geometric Tolerancing: Ensuring components meet specific geometric requirements like parallelism, roundness, and flatness.

- Surface Roughness: Measuring the texture of a surface for optimal performance and functionality.

Our experienced metrology technicians meticulously inspect every component, ensuring they meet or exceed your specifications. We provide detailed inspection reports, allowing you to visualize and understand the results.

Metrology is not just a process; it’s a core principle at LBC. It allows us to deliver exceptional quality and give you the confidence that your project components are built to the highest standards.

LINEAR HEIGHT GAUGE (TRIMOS V3)

- Measuring Range : 407mm / 16"

- Application Range : 508mm / 20"

- Max. Resolution : 0.001mm / 0.00005"

- Measuring Force : 0.75 / 1.5 N

- Max Permissible Errors : 7μm

- Repeatability : 2 (Ø: 4) μm

- Frontal Squareness Deviation : 10μm

Unit

1

- Measuring Range : 711mm / 28"

- Application Range : 812mm / 32"

- Max. Resolution : 0.001mm / 0.00005"

- Measuring Force : 0.75 / 1.5 N

- Max Permissible Errors : 8μm

- Repeatability : 2 (Ø: 4) μm

- Frontal Squareness Deviation : 15μm

Unit

2

SW VISION VIDEO MACHINE

- Measuring Range (mm) : X=300, Y=200, Z=200

- X,Y Accuracy (μm) : 2.0+L/200

- Z Accuracy (μm) : 5.0+L/200

- X,Y Accuracy Vector (μm) : 2.5+L/200

- Resolution : 1μm / 0.5μm (optional)

- Optical Zoom : 0.7-4.5X step lens (1:6.5)

Unit

1

WENZEL XO 5.10.5 BRIDGE TYPE CMM

- Measuring Range (mm) : X=1000, Y=700, Z=500

- Measuring System : Optical division 20μm

- Resolution : 0.1μm

Unit

1

MAHR MARSURF PS 10

- Measuring Range (mm) : 350

- Resolution : 8 nm

- Measuring force (N) : 0,00075

Unit

1

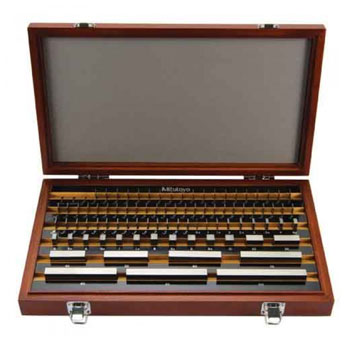

MICROMETER

PIN GAUGE

CALIPER