LBC Engineering

Products

Small Components

Small components are the unsung heroes of the engineering world. Often no bigger than your fingernail, these intricate parts play critical roles in countless devices, from smartphones to spacecraft.

They require meticulous design and precise manufacturing. Specialized equipment and skilled engineers ensure these miniature marvels meet exact specifications and tolerances.

Despite their size, small components can have a significant impact on a product’s performance and functionality. Their strength, weight, and material properties are crucial factors to consider.

LBC Engineering possesses the expertise and technology to craft these miniature masterpieces, bringing your vision for small components to life.

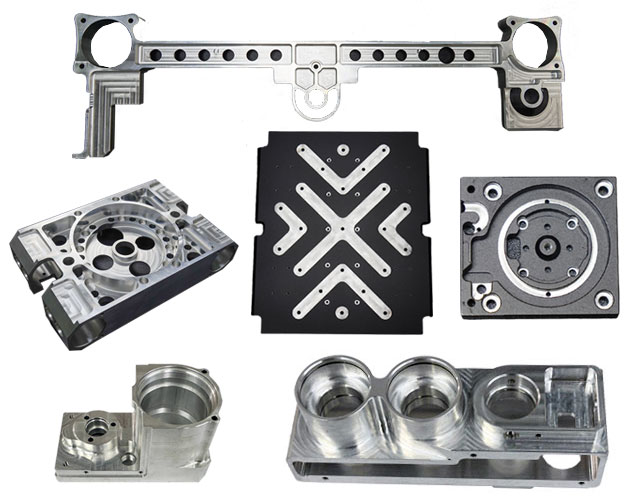

Complex Components

Complex components are the intricate building blocks that bring complex machinery and systems to life. Imagine an engine, a medical device, or a high-tech robot – each relies on these specialized parts to function flawlessly.

These components often feature:

- Tight tolerances, meaning their dimensions and specifications must be incredibly precise.

- Unique shapes and geometries, pushing the boundaries of design and functionality.

- High-performance materials chosen for specific strength, weight, and resistance.

Think of them as the intricate gears within a larger machine, each playing a crucial role in achieving the overall function and performance.

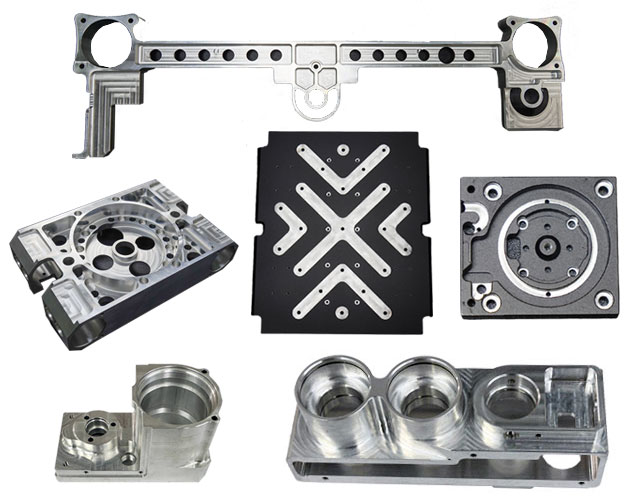

Complex Components

Complex components are the intricate building blocks that bring complex machinery and systems to life. Imagine an engine, a medical device, or a high-tech robot – each relies on these specialized parts to function flawlessly.

These components often feature:

- Tight tolerances, meaning their dimensions and specifications must be incredibly precise.

- Unique shapes and geometries, pushing the boundaries of design and functionality.

- High-performance materials chosen for specific strength, weight, and resistance.

Think of them as the intricate gears within a larger machine, each playing a crucial role in achieving the overall function and performance.

Casting Machining

Imagine starting with a rough shape, then transforming it into a precise, high-performance component. That’s the power of combining casting and machining.

Casting creates the initial form using molten metal poured into a mold. This process is ideal for complex shapes.

However, casting alone may not achieve the exact tolerances and surface finishes required. That’s where machining comes in.

Machining uses specialized tools to remove material from the cast part, achieving precise dimensions and smooth surfaces.

Combining these two processes allows you to create intricate, high-quality components efficiently.